What Are the Key Features of a High-Quality LED Panel Light?

Essential Characteristics of Premium LED Panel Lighting Systems

LED panel lights have revolutionized commercial and residential lighting with their sleek design and energy-efficient performance, but not all products deliver equal quality. Discerning buyers should evaluate several critical features when selecting high-performance LED panel lights that combine longevity, visual comfort, and technical excellence. From optical engineering to thermal management, superior LED panel lights incorporate advanced technologies that distinguish them from budget alternatives in meaningful ways. These lighting solutions must meet stringent requirements for color accuracy, glare control, and consistent output while maintaining reliability across thousands of operating hours. Understanding these key features enables informed purchasing decisions that balance upfront costs with long-term performance in various installation environments.

Optical Performance and Light Quality

Uniform Illumination Without Hotspots

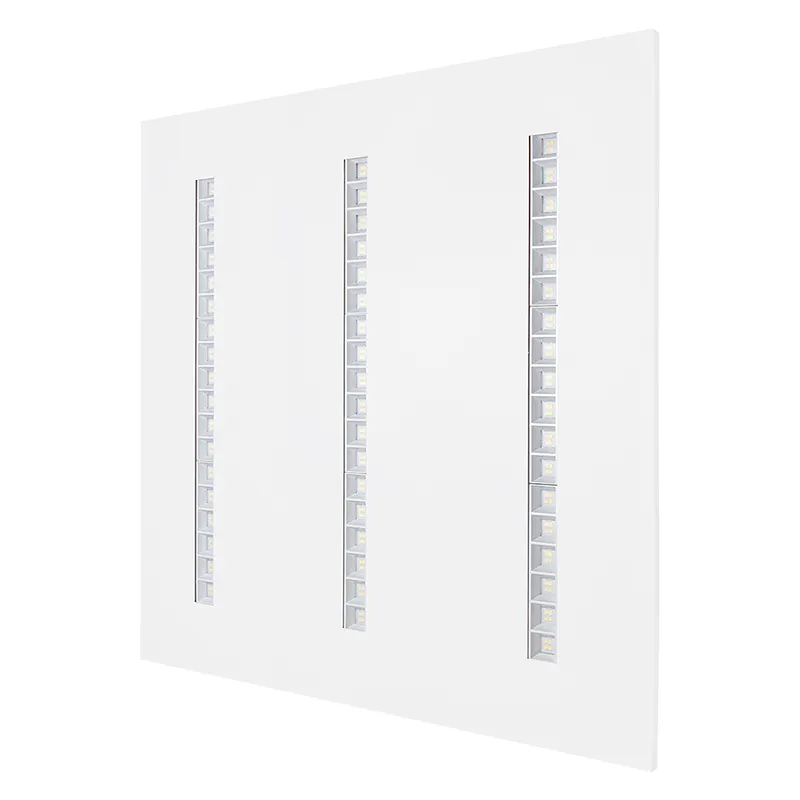

High-quality LED panel lights achieve perfectly even light distribution through sophisticated diffusion systems that eliminate visible diodes and dark spots. Multi-layer optical designs typically combine prismatic light guides with micro-textured diffusers to scatter light evenly across the entire panel surface. Premium models maintain consistent brightness levels edge-to-edge, with less than 10% luminance variation across the emitting area. This uniform output prevents the "checkerboard effect" common in inferior panels where individual LEDs become discernible during operation. Advanced light guide plates in better LED panel lights utilize laser-etched patterns that precisely control light direction while minimizing losses through the optical system. The result is comfortable, shadow-free illumination ideal for office environments, healthcare facilities, and retail spaces where visual clarity matters.

Superior Color Rendering and Consistency

Professional-grade LED panel lights exceed basic CRI (Color Rendering Index) requirements with ratings of 90+ for accurate color representation under artificial light. These high-CRI solutions incorporate carefully binned LEDs that maintain tight color consistency within a 3-step MacAdam ellipse, ensuring uniform white tones across multiple fixtures. Look for panels offering tunable CCT (Correlated Color Temperature) options with smooth transitions between warm and cool white spectrums for adaptable lighting scenarios. The best LED panel lights also minimize color shift over time through robust phosphor formulations and proper thermal management that prevents blue spike degradation. This attention to color quality makes the difference between lighting that merely illuminates and lighting that enhances visual tasks, merchandise presentation, or architectural details with true-to-life color fidelity.

Electrical and Thermal Engineering

High-Efficiency Driver Technology

The driver represents the heart of a reliable LED panel light, with premium models featuring industrial-grade drivers that deliver 90%+ conversion efficiency. Look for constant current drivers with universal voltage input (100-277V) that maintain stable output despite line fluctuations common in commercial buildings. Advanced protection circuits should guard against power surges, short circuits, and thermal overload to prevent premature failure. Dimmable LED panel lights of quality incorporate either 0-10V, DALI, or PWM control protocols with smooth, flicker-free performance across the entire dimming range. Some high-end models now include smart-ready drivers compatible with IoT lighting systems for future upgrade potential. These electrical components directly impact the panel's lifespan, with top-tier drivers rated for 50,000+ hours of operation while maintaining 90% lumen maintenance at end-of-life.

Advanced Thermal Management Systems

Effective heat dissipation separates professional LED panel lights from budget models, directly affecting both performance and longevity. Aluminum chassis designs should incorporate heat sink fins or thermal channels that passively cool LED arrays without requiring noisy fans. High-quality panels maintain junction temperatures below 85°C even in enclosed ceiling installations, preventing accelerated lumen depreciation. Thermal interface materials between LED boards and housing should use premium thermal pads or phase-change compounds rather than basic adhesives. Some manufacturers implement temperature monitoring circuits that automatically reduce output if overheating occurs, protecting components while maintaining safe operation. Proper thermal design ensures the LED panel light maintains 95% of initial lumen output after three years of continuous operation, far outperforming cheaper alternatives that degrade rapidly under thermal stress.

Mechanical Design and Build Quality

Robust Housing and Suspension Systems

Commercial-grade LED panel lights feature durable aluminum alloy frames that resist warping while providing secure mounting options. Look for panels with reinforced corners and tension-balanced suspension systems that prevent sagging in large ceiling grids. The housing should achieve IP54 rating or better for dust and moisture resistance in challenging environments. High-quality edge-lit panels use seamless extruded aluminum frames that eliminate light leaks while providing structural rigidity. For recessed installations, look for panels with tool-less mounting clips and adjustable tension springs that accommodate various ceiling tile thicknesses. These mechanical features ensure the LED panel light maintains perfect alignment and professional appearance throughout years of service, even in high-traffic areas subject to building vibrations or maintenance activity.

Serviceable Components and Modular Design

Superior LED panel lights offer field-replaceable components that extend usable life beyond typical disposable fixtures. Modular designs allow separate replacement of drivers, LED arrays, and optical components as needed rather than discarding entire fixtures. Tool-accessible compartments simplify maintenance without requiring complete fixture removal from ceilings. Some manufacturers provide component-level spare parts with cross-reference documentation for easy identification. This service-friendly approach reduces long-term ownership costs and prevents unnecessary e-waste when only specific elements require renewal. The best LED panel lights also feature daisy-chain wiring capabilities and standardized connectors that simplify large-scale installations and future reconfigurations without custom electrical work.

Smart Features and Control Integration

Advanced Dimming and Scene Control

Next-generation LED panel lights offer intelligent control capabilities that basic models lack. Look for panels with embedded light sensors that enable automatic daylight harvesting and constant lux maintenance algorithms. Premium systems provide programmable scene control with preset lighting recipes for different activities or times of day. Some high-end LED panel lights now incorporate occupancy sensing and adaptive dimming that responds to room usage patterns. These smart features should operate without visible stepping or flicker across the entire dimming range, maintaining smooth light transitions that prevent eye strain. Control options increasingly include wireless protocols like Bluetooth Mesh or Zigbee for flexible system design without additional wiring. This level of controllability transforms LED panel lights from simple illumination sources into responsive elements of smart building ecosystems.

Network Integration and Data Capabilities

Commercial-grade LED panel lights are evolving into connected devices that provide operational data and system diagnostics. Look for fixtures with built-in power metering that tracks energy usage and identifies potential issues before they cause failures. Some advanced models now feature performance logging that records operating hours, temperature history, and output levels for predictive maintenance. Network-enabled LED panel lights can integrate with building management systems via open protocols like BACnet or KNX for centralized monitoring. These data capabilities allow facilities teams to optimize lighting performance, schedule maintenance during low-usage periods, and verify system-wide energy savings. The most sophisticated LED panel lights even support over-the-air firmware updates to add features or improve performance throughout the product lifecycle.

FAQ

How long should a quality LED panel light last?

Premium models maintain 70% lumen output for 50,000-100,000 hours with proper thermal management and quality components.

What's the difference between edge-lit and back-lit LED panels?

Edge-lit uses peripheral LEDs with light guides for ultra-slim profiles, while back-lit places LEDs directly behind the diffuser for better uniformity in thicker panels.

Can LED panel lights be used with emergency backup systems?

High-quality models offer compatible emergency battery options that provide 90+ minutes of illumination during power outages.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL VI

VI ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS GA

GA IS

IS